The demand for locally sourced and artisanal products has never been higher, and Connecticut farmers are rising to the challenge. The proliferation of farmers’ markets in our region reflects a growing desire on the part of consumers to know where their food — and handcrafted goods — are coming from. In fact, a recent study conducted by University of Connecticut found that 60 percent of Connecticut consumers were willing to pay a premium for products labeled Connecticut grown.

Not surprisingly then, homegrown businesses are thriving on area farms. Our state was home to almost 6,000 farms when the last U.S. Census was completed, an increase of more than 20 percent over the last decade. In addition to the more customary offerings — like produce, animal and dairy products — many of today’s farmsteaders are also entrepreneurs, launching small-scale businesses from their farms and selling everything from bath and body products to specialty foods to clothing.

Lyric Hill Farm, Granby

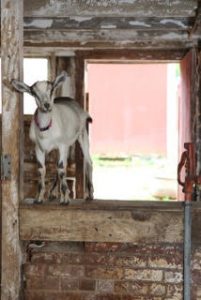

“Baby P,” the not-yet-named goat that follows Nancy Butler around Lyric Hill Farm as if it thinks she’s his mother, was born shortly before Butler’s daughter Mollie moved across the country.

“I call him my ‘replacement kid,’ ” says the Granby-based soap maker. But Butler blames her son Austin, who went off to college around the time that Baby P’s mother arrived, for the unlikely deviation in her career path.

The Granby mother of four (she has another son, Ethan, and an adult stepdaughter, Corinna), studied geology and civil and environmental engineering at Cornell University as a college student. She then spent 10 years as an environmental and safety engineer at Travelers insurance company, and did stints as both a garden adviser at White Flower Farm in Morris and a master gardener/horticulturist at West

Hartford’s Westmoor Park, before starting her now-thriving goat milk soap and laundry detergent business.

Butler and her husband, Don, bought their first pair of goats in 2008 to indulge Austin, who, as a third grader, became enamored with their friend’s goats and decided he, too, wanted to start raising and showing the animals. He learned how to care for them through a local 4-H farm program, and showed them for three years. “Then he hit puberty,” recalls Butler, “and decided that goats are not nearly as cool as the guitar, which you don’t have to leave your room twice a day to milk.”

Butler and her husband, Don, bought their first pair of goats in 2008 to indulge Austin, who, as a third grader, became enamored with their friend’s goats and decided he, too, wanted to start raising and showing the animals. He learned how to care for them through a local 4-H farm program, and showed them for three years. “Then he hit puberty,” recalls Butler, “and decided that goats are not nearly as cool as the guitar, which you don’t have to leave your room twice a day to milk.”

By then, she was too attached to the animals to part with them. After several months of using the goats’ abundant supply of milk to make cheese, which found its way into every family meal, her children rebelled, and she turned to soap-making instead.

“I have approached soap-making as I bake — using the freshest, highest quality ingredients I can get,” says Butler. In addition to using milk from her own goats, which is pesticide-, hormone- and antibiotic-free, she infuses the soaps with herbs and botanicals like lavender, calendula, lemon verbena and white sage, all of which she grows on her farm. Every ingredient in each bar of soap — except the lye, which is needed to saponify the vegetable oils and turn them into soap — is food grade, she says.

Butler keeps eight Alpine goats, six of which have pedigrees whose lineage can be traced back to their French goat ancestors. “It’s not like we have a big herd — I know every one personally,” she says, pausing to say, “Hi, girls” to a group of goats that are grazing by the front barn.

“The soap supports my goat habit.”

She originally produced the soaps in a small kitchenette in the 1895 farmhouse she lives in with her family, but when racks of soap threatened to overtake her dining room, living room and sun porch, she moved the operation into a studio in one of several barns on her five-acre property. “When I first started out, on a really productive day I could make 60 bars of soap,” she adds. “Now I can make 500 in a day.”

She sells her soaps out of a charming milking house that has been standing on the property for over a century. Patrons, using the honor system, record their purchases in a little notebook and leave their money in a black mailbox hanging by the door. In addition to the beautifully wrapped soaps that fill a farmhouse sink, a long pine cupboard and an old breakfront in the tiny store, customers can also find old-fashioned tins of laundry detergent, as well as hand-knitted washcloths on display.

Butler originally developed the all-natural laundry detergent because a local laundromat was looking for an eco-friendly alternative to store detergents, but she now has many “detergent groupies.” The detergent is scented with essential lemongrass oil and is free of filler, anti-caking chemicals, and artificial fragrances.

She started knitting her own linen washcloths because she was “looking for something with a natural fiber that wouldn’t take my skin off, and couldn’t find something that wasn’t made in China.” Though the linen is imported from Belgium, it is spun to her specifications at a mill in Rhode Island. “I’m always trying to expand in a way that is eco-conscious and local,” she says.

Butler, who is passionate about community outreach, and “making sure that agriculture and farming is real to people,” periodically visits local libraries to introduce local children to her Alpines. “I’m a small enough farm that I can drop what I’m doing if someone wants to come and see a baby goat,” she adds.

She also sells her products online and at about 20 independent shops in Connecticut and Massachusetts.

“I feel very strongly about only placing my products in businesses that really give back to their local communities, ” says Butler. She donates a portion of her proceeds to Heifer International, a charity that gives goats and other livestock to families in developing countries to help them earn a living.

Ashlawn Farm Coffee, Old Saybrook

When Carol Adams first bought a roaster and started roasting her own coffee in an old barn on the Lyme, Connecticut, farm she shared with her then-spouse, Chip Dahlke, she never expected to be running a full-service cafe and selling her beans to restaurants and specialty grocers across Connecticut. “I really thought this would be some kind of glorified hobby,” she confesses.

It all started one morning when she woke up and realized she was out of coffee. “I was so desperate that I brewed a stale packet of Cape Cod Coffee Roasters decaf from a hotel I had stayed at two years earlier,” Adams recalls.

“It occurred to me that, wow, coffee had always been the drink of the farm. If they roasted it in Cape Cod, why couldn’t I learn to roast it here?”

Fast forward 16 years, and not only does Adams produce 27 varieties of coffee under the name Ashlawn Farm Coffee, named for the roastery’s birthplace, she also runs a café by the same name next to the Old Saybrook train station. The café attracts a steady flow of “coffee geeks and gourmands” from near and far, she says, including local devotees, train commuters, and regulars from the days when a smaller café was housed in a red barn perched above the farm’s picturesque cow pastures.

Soon after that fateful morning when Adams realized she could roast her own coffee, she found herself in Florida, taking a three-day coffee-roasting workshop offered by the company that sold her the roaster.

“I came back realizing that people were going to want to taste what we were going to roast, to learn what they liked and would want to buy,” she says. So she created a tiny “tasting room,” which was slowly expanded over time and gradually evolved into the original Ashlawn Farm Café in Lyme. That café became so popular that Adams opened a second one in Old Saybrook in 2013.

The coffee business was definitely a departure for Adams. In her former life, she taught English at a middle school in North Haven. She met and married Dahlke in 1996 and moved onto Ashlawn Farm, which had been in Dahlke’s family since 1909. Following her divorce in 2016, Adams closed the original café and moved the roasting operation to the Old Saybrook location.

Today, Adams serves 300 to 400 customers each day in the café, and the large stainless steel coffee roaster roars to life daily in a barnlike space next door. Bins lining the walls of the roastery contain green coffee beans representing every coffee-growing continent in the world, from South and Central America to Africa. There are single-origin beans, from places like Sumatra and Nicaragua and Zambia — and several blends, including “Black Angus,” in honor of the bovine residents of Ashlawn Farm who once grazed outside the original roasting barn.

Every day, the green Arabica beans (they are all Arabica; that is, they have been handpicked in the mountainous areas where they are grown) are dumped into the roaster, where they attain the rich brown color that most people associate with coffee beans.

Some of the freshly roasted beans will be served or bagged up and sold at the café; others will be distributed to about 60 restaurants and specialty grocers around the state, and even a couple in Rhode Island and New York.

Ashlawn Farm Coffee roasts and sells 1,000 to 1,500 pounds of coffee per week.

Thorncrest Farm & Milk House Chocolates, Goshen

“Nowhere else on Earth can you enjoy a ‘single cow origin’ chocolate,” states a sign posted on the wall inside the circa 1895 milk house from which Kimberly Thorn sells her delectable European-style chocolates.

“Nowhere else on Earth can you enjoy a ‘single cow origin’ chocolate,” states a sign posted on the wall inside the circa 1895 milk house from which Kimberly Thorn sells her delectable European-style chocolates.

Only Daydream, a 7-year-old Jersey, provides the naturally sweet milk that can produce the buttery and vanilla tones in Thorn’s chocolate encased caramels. The dark chocolate ganache inside the “Brigadoon,” she says, gets its velvety finish from the rich milk of Valor, a 4-year-old Holstein. Indeed, according to Thorn, the stress-free bovines at Thorncrest Farm are the secret ingredient behind the success of her artisanal chocolate business.

“Our cows are bred for the flavor of milk that they provide,” says Thorn. “Any time a cow is stressed, it will affect the flavor of the milk. We focus on keeping our cows stress free.” That job falls predominantly to her husband, Clint, and their two sons, Garret and Lyndon, who ensure that everything from the hay the cows eat, to the feng shui-inspired barn they relax in is designed to support a stress-free existence.

“Clint designed the whole barn for the cows’ health and comfort,” she says. For example, relying on the natural westerly breezes allows the air to flow through the open doors at either end of the barn. The cows are positioned so that they face north to south, rather than east to west, because it is the orientation they instinctively opt for. “If you watch cows, or animals in general,” she explains, “they tend to lay in a certain direction.”

The inspiration for Milk House Chocolates came while she was working on a thoroughbred stud farm in Ireland in 1984, and befriended a local dairy farmer who was providing the milk, cream and butter from his farm to a little pastry shop nearby.

“I actually fell in love with the shop and the entire idea,” she recalls. When Clint, then her boyfriend, came to visit, she took him there for lunch. “We were sitting out on the grass and saying, ‘Wouldn’t it be great to do this kind of thing with this same connection to our cows?’ ” she says. The two traveled together to France and 13 other countries (living on chocolates, wine and an occasional slice of bread), which is where she first came across small artisanal chocolate shops. “That’s where the idea of us combining the cows with chocolates was born.”

Clint grew up on a dairy farm in Goshen and had always had cows. The couple, who were married when they returned from Europe, started farming together on the original Thorncrest Farm property (the couple moved their milk-and-chocolate operation around the corner six years ago).

With the exception of two light brown Jersey cows, including Daydream, and a handful of Longhorns that they breed for, well, their long horns, most of their 60-cow herd consists of black and white dappled Holsteins.

The true secret behind the chocolate flavors is Hanover Hill Jethro Koral, a Holstein cow from Port Perry, Ontario, who is the basis for their herd. Her pedigree, according to Thorn, extends back to “the greatest flavor cows in the history of the breed.” Clint breeds the cows for the flavor of the milk they provide. Thorn uses that milk to create more than 120 different seasonal varieties of her unique chocolate confections.

In 1997, she discovered which cows’ milk worked best for chocolates through trial and error and invented the single-cow chocolate idea.

“Certain cows provide milk that allows other flavors to “maintain a consistent profile on your palate,” Thorn explains. In other words, she says, the milk doesn’t overpower the chocolate, and thus the chocolate doesn’t overpower the other elements in her confections, which might include garden herbs or orchard fruits, all organically grown and freshly harvested from her farm.

There are bonbons infused with mint, thyme, lemon verbena, and curry; customers love Daydream’s milk chocolate caramels, as well as her Valor’s black pepper ginger truffles and dark chocolate lavenders.

“Most of my chocolates have more of a longer finish than a boastful beginning,” she says, arguing that like a fine wine, every chocolate — and the milk that goes into it — has a distinct profile. “Their smell is different, their taste, the texture on your palate — it’s unique and very special to each one.”

Customers can order her chocolates online. She has shipped to every state in the country as well as Europe. Her only non-virtual marketplace is on the farm.

“I really want to keep it artisanal, for everything to be fresh and what I could make myself,” says the chocolate-maker. “I love the fact that I can create new flavors from the cows and bring about a culinary journey for everyone, in a sense, to experience the cows and what’s growing on the farm through classic old-world style chocolate.”

Clatter Ridge Farm, Farmington

Historic preservationists Bobbie Emery and Anne Foss were doing a project at the Hill-Stead Museum in Farmington back in 2002, when Emery suggested that adding sheep to the property, to graze beside the 1901 homestead’s old barns along Route 4, would “put the estate’s farm complex into context.”

Historic preservationists Bobbie Emery and Anne Foss were doing a project at the Hill-Stead Museum in Farmington back in 2002, when Emery suggested that adding sheep to the property, to graze beside the 1901 homestead’s old barns along Route 4, would “put the estate’s farm complex into context.”

Museum administrators responded that they didn’t have the funds to buy sheep, Emery says, so she offered to purchase a couple of animals for them. “They said. ‘We can’t afford to take care of the sheep,’ ” she recalls, “so we said we would.”

The then-novice shepherds raised their first pair of lambs on Clatter Ridge Farm, which had been in Emery’s family for more than a century and where the two had just built a farmhouse together, “just to make sure we could take care of sheep,” Emery says.

Fifteen years later, Emery and Foss’s shepherding business has outpaced their historic preservation business. The pair tends a flock of about 60 Shetlands, both at Hill-Stead and on pastures at and near their farm, producing about 100 pounds of wool per year. The wool is turned into a variety of natural fiber products that are sold online, as well as at the Hill-Stead Museum Store, where they are displayed alongside reproductions of the museum’s impressionist paintings and other local artisanal offerings. Every wool hat, pair of gloves, scarf and throw bears the name of the sheep who “proudly produced” the item.

Though the two continue to operate East/West Builders, their preservation business, and still do restoration work for the Hill-Stead, they are more often found on the pastures at the north end of the landmark estate, tending to their Shetlands.

“Farmington has a rich agricultural history and it’s cool to drive into Farmington and see the sheep grazing here,” says Emery. She notes that their Shetlands, a “heritage breed of fiber sheep,” are not only hardy, but produce a very fine wool.

“I have sensitive skin, but I wear our wool socks nine months out of the year,” she says. Foss also notes that the breed’s natural variation in color adds to their desirability. Indeed, the pasture at Hill-Stead is dotted with sheep in an assortment of grays, browns and whites. These same natural shades can be found in the herringbone and braided plait patterns on their woolen throws.

Clatter Ridge Farm also participates in the Connecticut Blanket Project, a cooperative initiative designed to support the state’s shepherding industry by producing blankets made entirely of wool from Connecticut sheep farms. Each year, they contribute wool for (and eventually sell) a blanket made through this volunteer effort that is modeled after the blankets once made by the Charles W. House & Sons Company in Unionville.

Along with their natural wool products, Foss and Emery also run a year-old “online farmers market,” through which they sell — and hand-deliver — their own lamb, pork, free range eggs, shitake mushrooms and maple syrup, as well as dairy, organic produce, meat and poultry from other farms in the area. “We’d like to be among those raising awareness of the importance of local farms and food that is grown near you,” notes Foss.

Foss and Emery are dedicated to sustainable farming. Not only are their lambs raised on pasture, but their pigs are born and raised in the forest, and their chickens are free range and cage free. The pair is also passionate about the need to preserve the state’s agricultural heritage. “People need to think of what they want Connecticut to look like in 10 years,” Emery says. “Local people buying local products is the only way we preserve our farms.”

Lori Miller Kase is a freelance writer living in Simsbury.

Photography by Todd Fairchild. Todd Fairchild of West Hartford is a longtime contributor to Seasons. For more about Todd, go to shutterbugct.com.

More Stories

Over 50, Underestimated: The Grandfluencers Redefining Age on Social Media

Building Resilient Businesses: Strategies for Success

Summer Means Convertibles